From Check-In to Take-Off: How LG Chillers Ensure Reliable Airport Cooling

From office towers to shopping malls – and even nuclear power plants – chillers are the unsung heroes of climate control. But when it comes to airports, the challenge is on a whole different level. These massive hubs run 24/7, with thousands of people moving through terminals, baggage areas, control rooms and retail spaces. That means the cooling systems have to be rock-solid, efficient and ready for anything.

At LG, we’ve made it our mission to deliver that kind of performance. Our high-efficiency chillers are designed to keep indoor conditions comfortable while making the most of every bit of energy. And airports around the world are proving just how reliable our solutions can be in some of the most demanding environments out there.

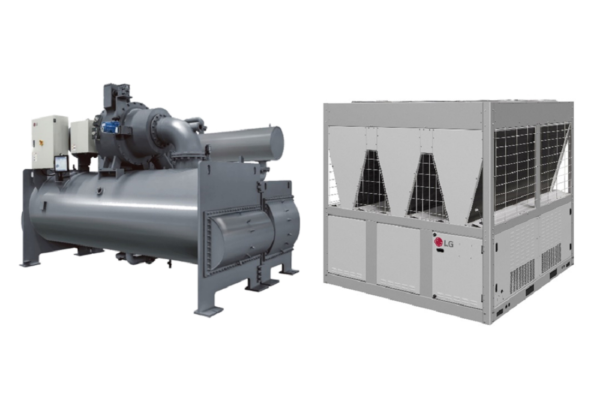

We know that no two airports are exactly alike, so we tailor our cooling solutions to each location. Our lineup includes Absorption, Centrifugal, Water-Cooled Screw, Air-Cooled Screw and Inverter Scroll Chillers – each with specialized technology and precise control systems. Whether it’s a scorching desert climate or a humid coastal city, our chillers adapt to keep things running smoothly.

Take King Khalid Airport in Riyadh, Saudi Arabia. We installed five Centrifugal Chillers there, each with a 3000 Refrigeration Ton (RT) capacity. Using two-stage compression, they deliver top-tier performance while minimizing energy consumption. We’ve also brough Centrifugal Chillers to airports in Bangladesh and Indonesia, helping them maximize cooling efficiency for their large-scale facilities.

In Brazzaville, Congo, Maya-Maya Airport now runs on Water-Cooled Screw Chillers. These units are built for stability, with advanced protection devices and precise control, and to celebrate this achievement, we hosted a commemorative installation ceremony on September 12.

Over in Mexico City, Benito Juarez Airport relies on our Air-Cooled Screw Chiller to keep passengers comfortable. It runs quietly, with low vibration, and uses a high-performance control algorithm to optimize output. By using a falling film evaporator and electronic expansion valve, it also enhances heat transfer efficiency, reduces refrigerant charge and precisely manages refrigerant flow.

Here at home in South Korea, our chillers are hard at work in multiple airports. Incheon International Airport runs eight Air-Cooled Screw Chillers for consistent cooling, while other major airports such as Gimpo and Jeju operate Absorption models with low-GWP refrigerant for stability and efficiency, alongside Centrifugal and Water-Cooled units.

These projects are just the beginning. The global chiller market is expected to hit USD 12 billion by 2027, and we’re aiming to grow our chiller business to USD 720 million (KRW 1 trillion) within two years. With advanced technology, diverse product lineup and commitment to customized solutions, we’re ready to keep airports – and industries everywhere – cool, comfortable and energy-smart.

# # #