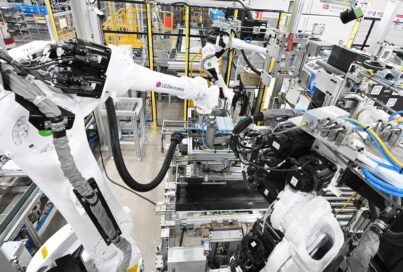

LG Expands Into Smart Logistics, Building on Lighthouse Factory Expertise

Strategic Partnership With LogisValley Aims to Scale AI-powered Autonomous

Robotics From Smart Factories to Global Logistics Hubs

SEOUL, July 1, 2025 — LG Electronics (LG) is expanding its smart factory innovations into the rapidly evolving smart logistics sector. The company recently signed a memorandum of understanding (MOU) with LogisValley at LG Digital Park in Pyeongtaek, Korea. The agreement marks a significant milestone in jointly developing next-generation logistics center solutions by combining the two companies’ respective strengths.

As Korea’s largest integrated logistics company, LogisValley provides comprehensive services in logistics center development, leasing and consulting to a wide range of domestic and global clients. The company also directly operates over 50 logistics centers around the world.

The partnership is grounded in a shared goal: to deliver customized smart logistics solutions that address the evolving needs of global customers. This will be achieved by integrating LG’s expertise in industrial robotics and digital twin technologies with LogisValley’s capabilities in logistics center design, construction and operations.

A Strategic Alliance for Smart Logistics Transformation

Through this collaboration, the two companies will work together to advance smart logistics solutions and pursue joint go-to-market strategies targeting global customers. Notably, LG will collaborate with LogisValley from the early design stages of new logistics centers to ensure optimal integration of LG’s smart factory technologies, maximizing synergy and operational efficiency.

LG’s smart factory portfolio encompasses a wide range of capabilities, including industrial robots, digital twin-based production system design and monitoring, and big data and generative AI-powered process, safety and quality management. These solutions are expected to generate significant impact in logistics operations, where accuracy and efficiency are key.

A major focus will be automation. LG’s broad lineup of robots – such as autonomous mobile robots equipped with robotic arms – can automate labor-intensive logistics tasks like box picking. Vision AI technology minimizes errors in packaging and product sorting, enhancing precision and reducing reliance on manual labor.

In addition, LG’s extensive experience in managing large volumes of manufacturing components across its production sites enables the company to provide automation solutions that optimize space utilization. By efficiently categorizing and storing items, LG’s solutions facilitate robotic outbound processes within logistics centers.

Digital twin technology serves as another key differentiator. By creating virtual replicas of logistics environments, LG can simulate and analyze material flows to design the most effective robotic workflows. These simulations allow optimization before deployment, while real-time monitoring helps proactively detect and address potential disruptions, improving overall operational efficiency.

Internal Deployment and Market Opportunity

Beyond third-party applications, LG and LogisValley will apply these smart logistics solutions internally to enhance their own operations. Customized systems will be implemented at LogisValley’s self-operated logistics centers and LG’s home appliance logistics hubs to further boost internal productivity and efficiency.

According to Fortune Business Insights, the global smart logistics market is expected to grow from USD 88.1 billion in 2025 to USD 212.8 billion by 2032, with a compound annual growth rate of 13.4 percent.

Broader Collaboration in Vietnam

In a separate initiative, LG and LogisValley have also signed an agreement to collaborate on a commercial development project in the West Lake district of Hanoi, Vietnam. The upscale complex will feature a six-star hotel and shopping mall, with LG providing a full suite of commercial display products and solutions.

Among the featured offerings by LG is its latest hotel TV – the first in the world to support both Apple AirPlay and Google Cast. Guests can stream content from their devices simply by scanning a QR code, with all personal data automatically erased at checkout to ensure privacy and security.

Other key offerings include the LG MAGNIT All-in-One, a 136-inch micro LED display with integrated controller and speaker, ideal for business environments, and a next-generation interactive whiteboard equipped with AI summary and chatbot features tailored for educational settings. All of these solutions can be integrated into LG’s Business Cloud platform, which provides seamless hardware-software management for commercial displays.

“This partnership is a major step forward in becoming a trusted partner in the fast-growing smart logistics industry,” said Jeong Dae-hwa, head of LG’s Production-engineering Research Institute. “By leveraging the logistics expertise we’ve built through operating our Lighthouse smart factories, we aim to create real value for our customers.”

“Our collaboration brings together LogisValley’s smart logistics platform and LG’s advanced factory technologies,” added Lim Young-bin, Chairman of LogisValley Group. “Together, we will accelerate innovation across logistics and manufacturing, and strengthen our global competitiveness.”

# # #

![[Executive Corner] Smart Factory: Ushering in a New Era of Manufacturing](https://www.lgnewsroom.com/wp-content/uploads/2025/06/Main-Image_Executive-Corner_Smart-Factory-402x272.png)