Seizing an Automated and Productive Future With Robots Built to Serve

From the best restaurants to the most expansive and complex warehouses, service and industrial robots are reshaping countless industries through impactful and groundbreaking advancements that bring the autonomous future a step closer. Enhanced efficiency, productivity and cost savings are just a few advantages of service and industrial robots.

In line with this, LG recently revealed its strategic investment in Bear Robotics as it doubles down on its commitment to advancing the capabilities of its service robotics, one of the company’s most promising business areas.

After a number of years innovating the robotics space, the LG CLOi lineup has evolved into ‘your best partner’ with a wide range of solutions that include LG CLOi ServeBot, LG CLOi GuideBot and LG CLOi CarryBot, powered by AI technology.

LG CLOi ServeBot’s independent suspension is implemented to all six wheels to ensure stable maneuverability across uneven floors. This enables the CLOi ServeBot to securely transport beverages and meals, including soups and noodles, even when travelling over surfaces with a slope of up to 5 millimeters (0.2 inches). And fully equipped with a LiDAR sensor and 3D camera, this technology lets the CLOi ServeBot navigate obstacles smoothly, ensuring that none of its valuable “cargo” is upset.

Offering next-level convenience to restaurant owners, LG CLOi ServeBot runs for 11 hours on a full charge and can be charged both automatically and manually. The latest model offers even more services, which means it can now carry out its serving duties and assist business owners with various tasks.

With its expanded tray size, the latest LG CLOi ServeBot now holds up to 40 kilograms, enabling it to transport all the dishes needed for western cuisine, which typically uses heavy tableware, or Korean cuisine, which comprises several side dishes. Extremely adaptable, the advanced robot’s trays can be completely removed or height adjusted to match different environments or applications. It even knows when the customer has picked up their plate so it can head straight back to the kitchen. On the other hand, if the tray is left full of tableware, then it automatically returns to its designated area.

LG CLOi ServeBot also provides entertainment including a CMS (Content Management System) that lets users upload content via their mobile device. Through its 10-inch display, customers waiting to be seated are shown the menu and entertaining videos to be pass the time. Additionally, android apps can be installed according to preference.

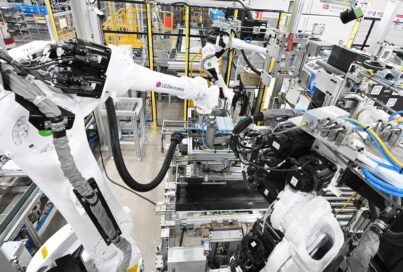

Going beyond its service robots, LG is proactively responding to the increasing need for robots in industrial settings with robotic innovations that boost productivity and quality in the manufacturing process. The company provides a variety of solutions that can be used to automate the warehouse.

LG unveiled its latest industrial robots at MODEX 2024, the largest supply chain logistics trade show in Atlanta, Georgia, USA. This included the new LG CLOi CarryBot family of Autonomous Mobile Robots (AMR), which are specially designed to navigate complex floor plans and deliver payloads in customizable configurations.

LG showcased two versions of LG CLOi CarryBot: a Mounting Type featuring two shelves which is ideal for smaller packages and navigating tight spaces, and a Rolltainer Type capable of carrying heavy loads on its back. This practical machine can quickly transport goods in large logistics sites at speeds of up to 1.2 meters per second, while providing stable driving by applying ‘Fast-X,’ LG’s autonomous driving technology optimized for logistics environments, including average driving and curve speed as well as acceleration and deceleration control.

In fact, the company has innovated a number of solutions to enhance factory efficiency. ‘Mobile Manipulator’ an autonomous driving-based vertical articulated robot that mimics human arm movements. Unlike conventional robots that usually carry out the same task repeatedly, Mobile Manipulators move around production lines and carry out various tasks such as transportation, product assembly and inspection. Another solution is LG’s low-floor AMRs, industrial logistics robots that can carry 500 kilograms from A to B with very little assistance, which not only makes production efficient but safe too.

To learn how LG is continuing to drive the commercialization of robotics in the real world while expanding its B2B businesses, stay tuned to LG Newsroom.

# # #